Purpose and Significance of the Research

Background and Purpose

Among industrial materials, only metals show high strength and large plasticity, so that metals and alloys are widely used as safe structural materials in our society. Nowadays, ultra-high strength is required to metallic materials for satisfying demands of huge constructions and light-weighting of transportation devices oriented to carbon-neutral (Fig.1). However, ductility and toughness in all kinds of materials deteriorate when strength increases. The present project aims to realize metals and alloys with both ultra-high strength and high toughness/ductility through their nano-structuring.

Novelty and Interests

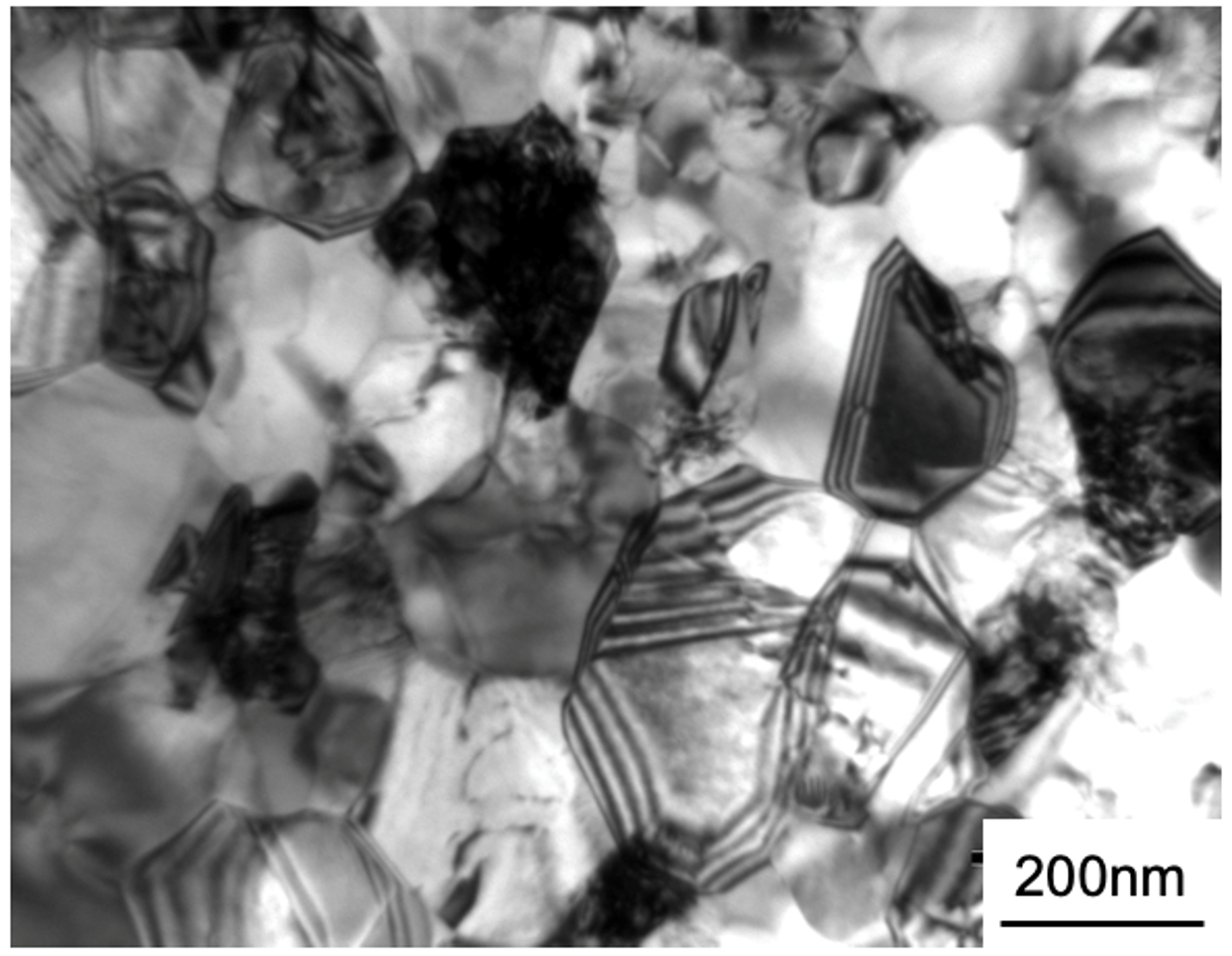

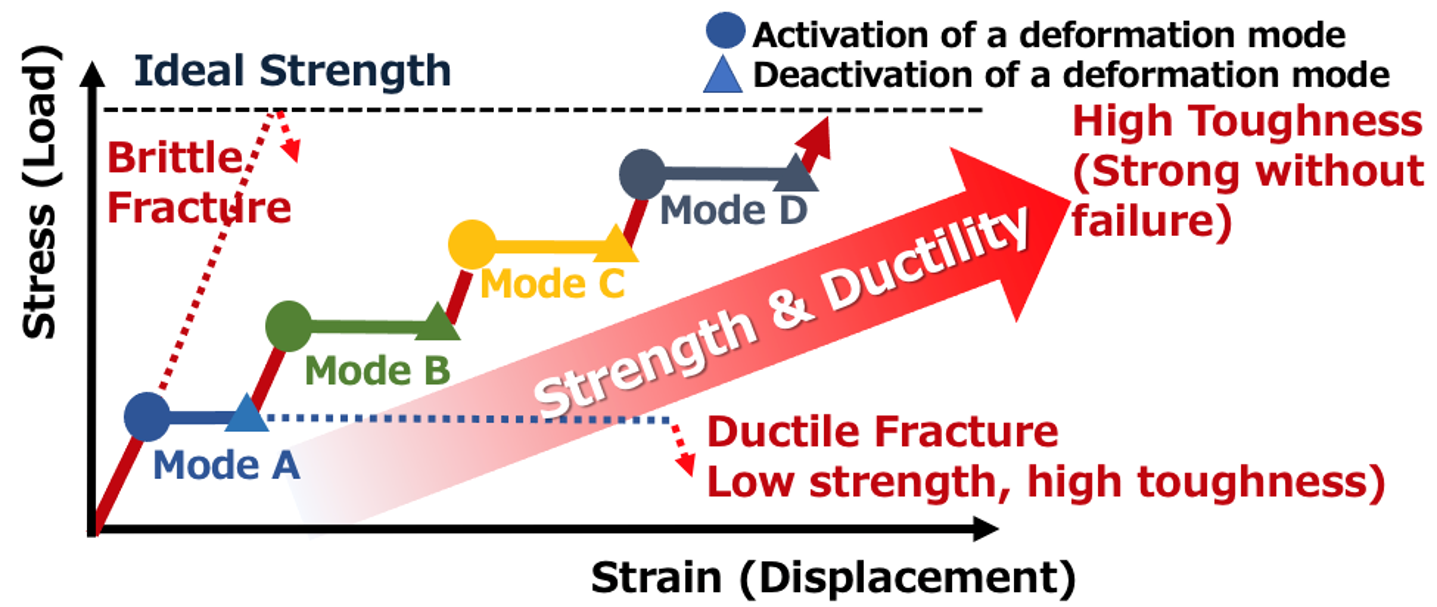

Solid metals have crystal structures constructed by periodical alignment of atoms. Metallic crystals are, however, not perfect but include various kinds of lattice defects that make variety of nano/microstructures with a wide range of length scales from several nano-meters (nm) to several tens micro-meters (mm). We have studied Bulk Nano-structured Metals (BNM: Fig.2) composed of grains smaller than 1 mm (=1000 nm) for a long time and have found some BNMs exceptionally managing both high strength and large ductility. In such BNMs, dislocation slip is significantly suppressed, while unusual deformation modes are activated, leading to enhancement of strain-hardening ability. Based on this finding, we propose a strategy to manage both ultra-high strength, approaching ideal strength and large ductility plus toughness through activating different deformation modes in BNMs (Fig.3). The international team pursue the fundamental principle of deformation mechanisms for realizing ultimate structural metallic materials by means of the state-of-the-art experimental and computational techniques.

Fig.1 Demands of huge constructions, light-weighting, and safety.

Fig.2 TEM image of a Bulk Nanostructured Metal.

Fig.3 Strategy to manage both high strength and large ductility.

Organization of the Project Team

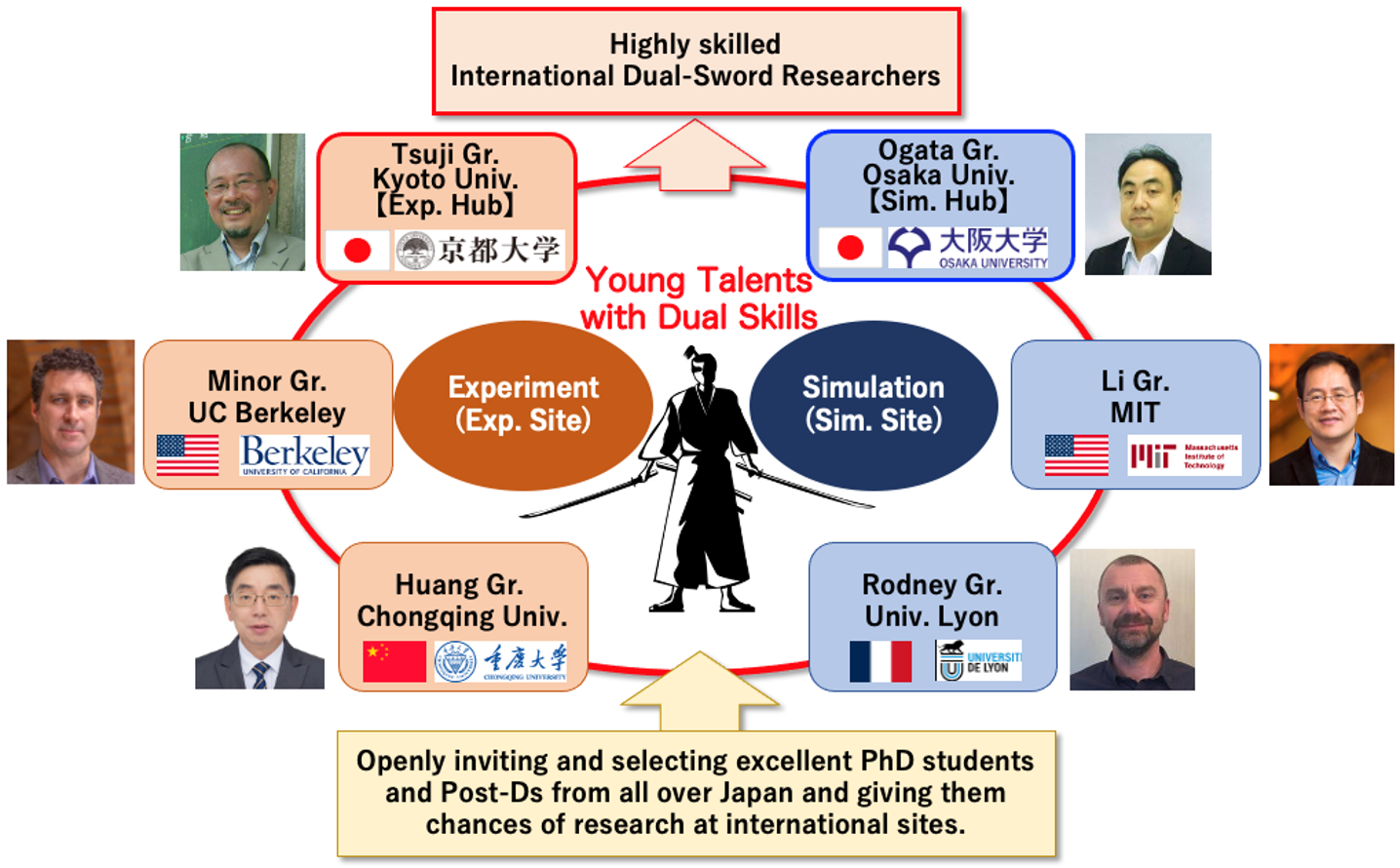

Figure 4 illustrates the international team of this project. World-leading scientists from four different organizations (Kyoto Univ., Osaka Univ., UC Berkeley, MIT, Chongqing Univ. and Univ. Lyon) carry out international collaborative works with young researchers for achieving the goal of the project. Kyoto U, UC-B and CQU conduct experimental works using technologies on materials processing, nanostructure characterization by advanced electron microscopy, and state-of-the-art deformation tests.Osaka U, MIT and U Lyon are in charge of theoretical and computational part using theories of dynamics and the state-of-the-art simulations. The young researchers are the main actors of this project. They can experience international collaborations at overseas sites of both experimental and computational studies, to become dual-sword talents for the next generation of materials science and engineering.

Fig.4 International collaboration team.

Plan for Fostering Early-career Researchers

Fostering Young Researchers Having Dual-Sword Skills

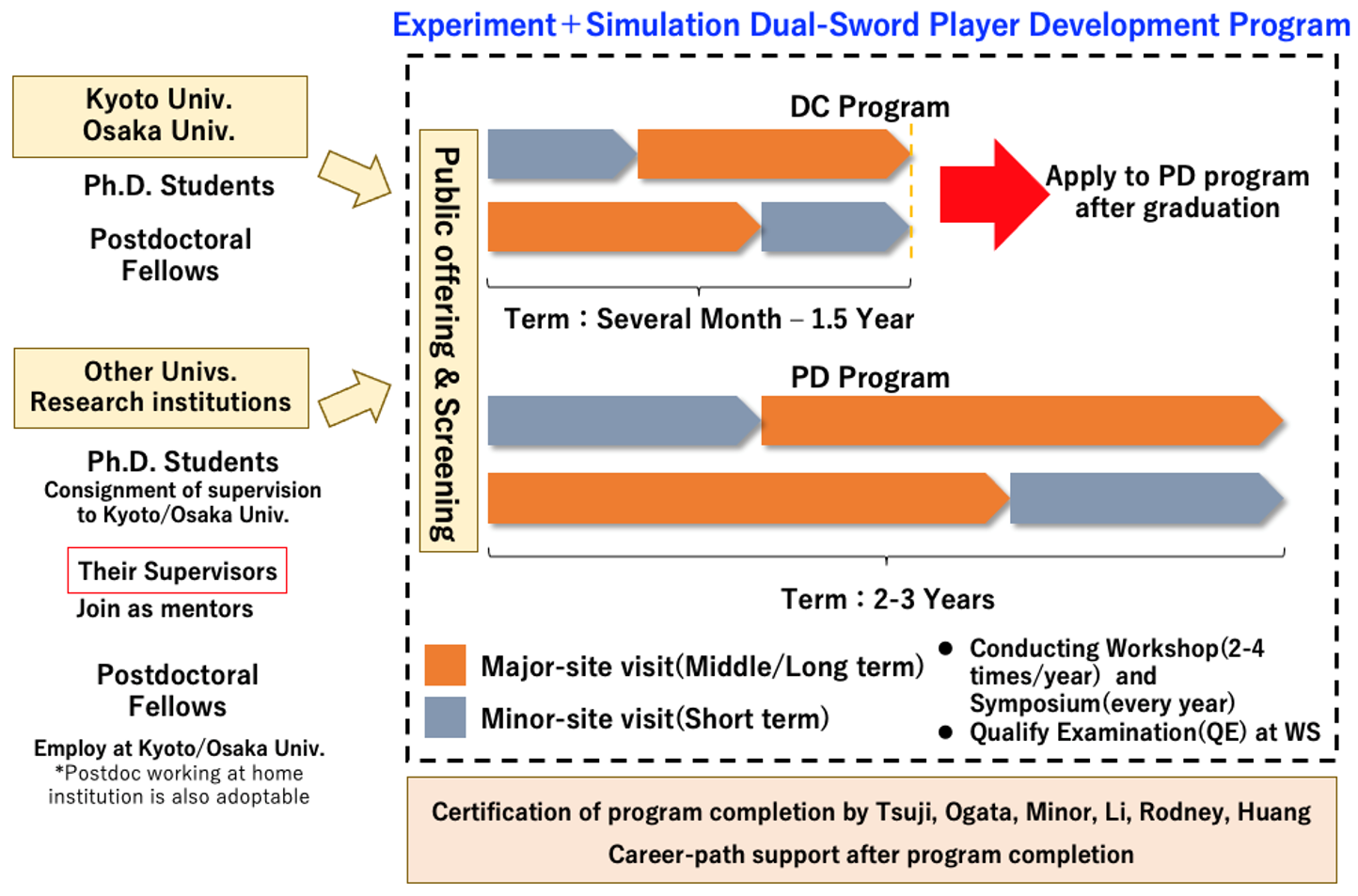

An important goal of this international leading program is to foster materials scientists in the next generation through international joint research. Particularly, this program aims to make dual-sword talents in both experimental and computational research. We expect that such young talents would change materials science, like Shohei Otani in MLB is changing the concept of baseball. Outline of the dual-sword program is shown in Fig.5. PhD students and post-D fellows are openly recruited from Japanese universities through public offering, and they can have chance to conduct research at international sites. The original supervisors of the candidates in other universities join the mentoring team, and the international sites can be added, depending on the subject of the young researchers. PhD students stay abroad for several months ~ 2 years, while post-Ds stay abroad for 2 ~ 3 years. We plan to send more than 12 young talents for DC and PD program.

Fig.5 Outline of the Dual-Sword program.